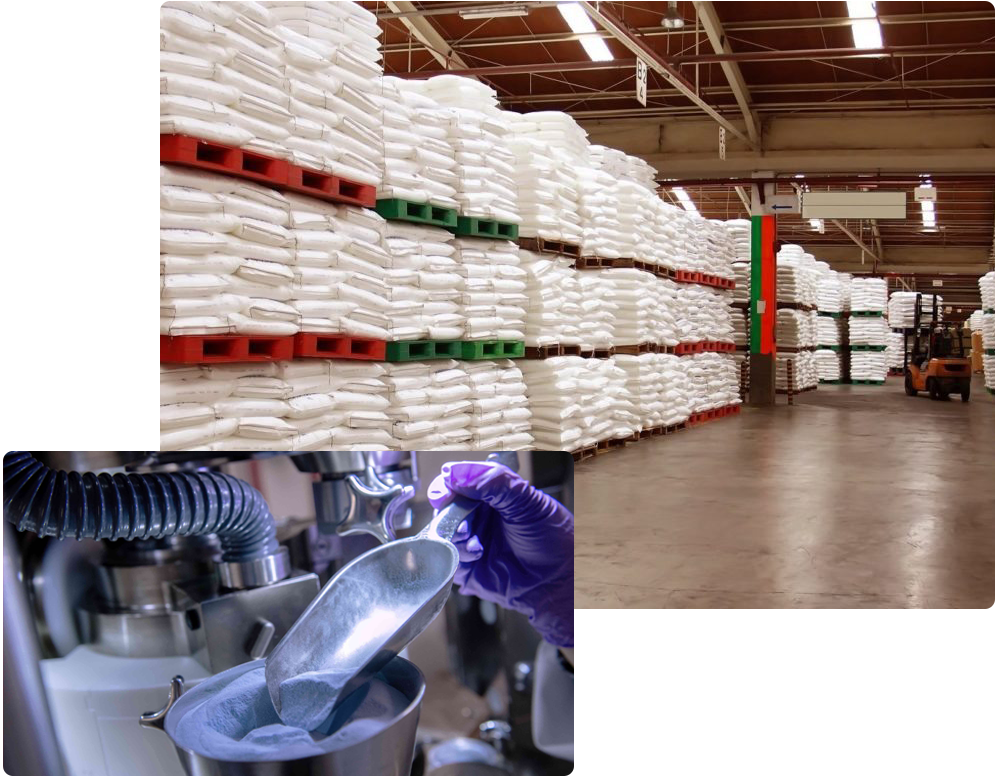

Raw materials play a crucial role in the pharmaceutical industry as they are the building blocks for the production of drugs and medications. These materials, also known as active pharmaceutical ingredients (APIs), are the substances responsible for the therapeutic effects of the drugs.

APIs are the primary raw materials in drug formulation. They are chemically active substances that have a direct impact on the treatment of a specific disease or condition. Excipients are non-active substances used in drug formulation alongside APIs. Solvents are used during the manufacturing process to dissolve APIs and excipients, facilitating their combination and formulation into a final dosage form.

In addition to the above, the pharmaceutical industry may use other raw materials such as antimicrobial agents, antioxidants, chelating agents, and pH modifiers. These materials assist in preserving the stability of the drug product, preventing microbial growth, and maintaining its quality over its shelf life.

Manufacturing pharmaceutical products such as tablets (tabs), syrups, and injections involves distinct processes and considerations.

Tablet: Tablets are solid dosage forms that contain one or more active pharmaceutical ingredients (APIs) along with excipients. The manufacturing process typically involves mixing, Granulation, Compression, Coating, and packaging processes.

Syrup: Syrups are liquid dosage forms containing dissolved or suspended APIs and flavoring agents. The manufacturing process typically involves the preparation of a solution or suspension, Mixing and Homogenization, Filtration, Flavouring and Sweetening, and packaging.

Injection: Injections are sterile formulations intended for parenteral administration. The manufacturing process for injections involves strict aseptic techniques and may vary depending on the type of injection (e.g., intravenous, intramuscular, or subcutaneous). Some general steps involved in injection manufacturing are Sterilization, Preparation of API Solution, Filtration and Clarification, Filling and Sealing, Quality Control, and packaging.

Pharmaceutical products require various types of storage facilities and conditions based on their specific requirements.

Ambient Storage: Ambient storage refers to storing pharmaceutical products at room temperature, typically between 20-25°C (68-77°F). This is the most common storage condition for many medications that do not require specific temperature controls. However, it's important to protect them from excessive heat, direct sunlight, moisture, and extreme temperature fluctuations.

Cold Chain Storage: The cold chain refers to the uninterrupted temperature-controlled storage and transportation of temperature-sensitive pharmaceuticals, especially vaccines and biologics. It involves maintaining specific temperature ranges from the point of manufacture to the point of administration, including storage, transportation, and distribution. Cold chain storage typically requires a combination of refrigeration and freezer storage facilities, as well as temperature-monitoring devices and transportation equipment.

In the pharmaceutical industry, transporting drugs and healthcare products requires careful consideration to ensure their integrity, safety, and efficacy.

Cold Van Transport: Cold van transport, also known as refrigerated van transport or temperature-controlled van transport, is equipped with refrigeration or cooling systems. This type of transport is specifically designed to maintain the desired temperature range throughout the journey, ensuring the integrity and stability of temperature-sensitive products.

Normal Van Transport: Normal van transport vehicles are those without specialized refrigeration or cooling systems. These vans do not provide temperature control and are suitable for products that do not require specific temperature conditions.

Export in the pharmaceutical industry refers to the process of selling and distributing pharmaceutical products to foreign markets or countries outside the company's home country. Pharmaceutical exports play a significant role in expanding the reach of pharmaceutical companies, accessing new markets, and meeting the healthcare needs of diverse populations.

Cold Chain Export: Cold chain export refers to the transportation of temperature-sensitive products, including pharmaceuticals, in a controlled and temperature-monitored environment throughout the export process. It involves maintaining the required temperature range from the point of origin to the final destination to ensure the integrity and efficacy of the products.

Normal Export: Normal export refers to the export without specific temperature controls or requirements. It typically involves shipping products that are stable at ambient temperatures and do not require specialized temperature-controlled packaging or transport.